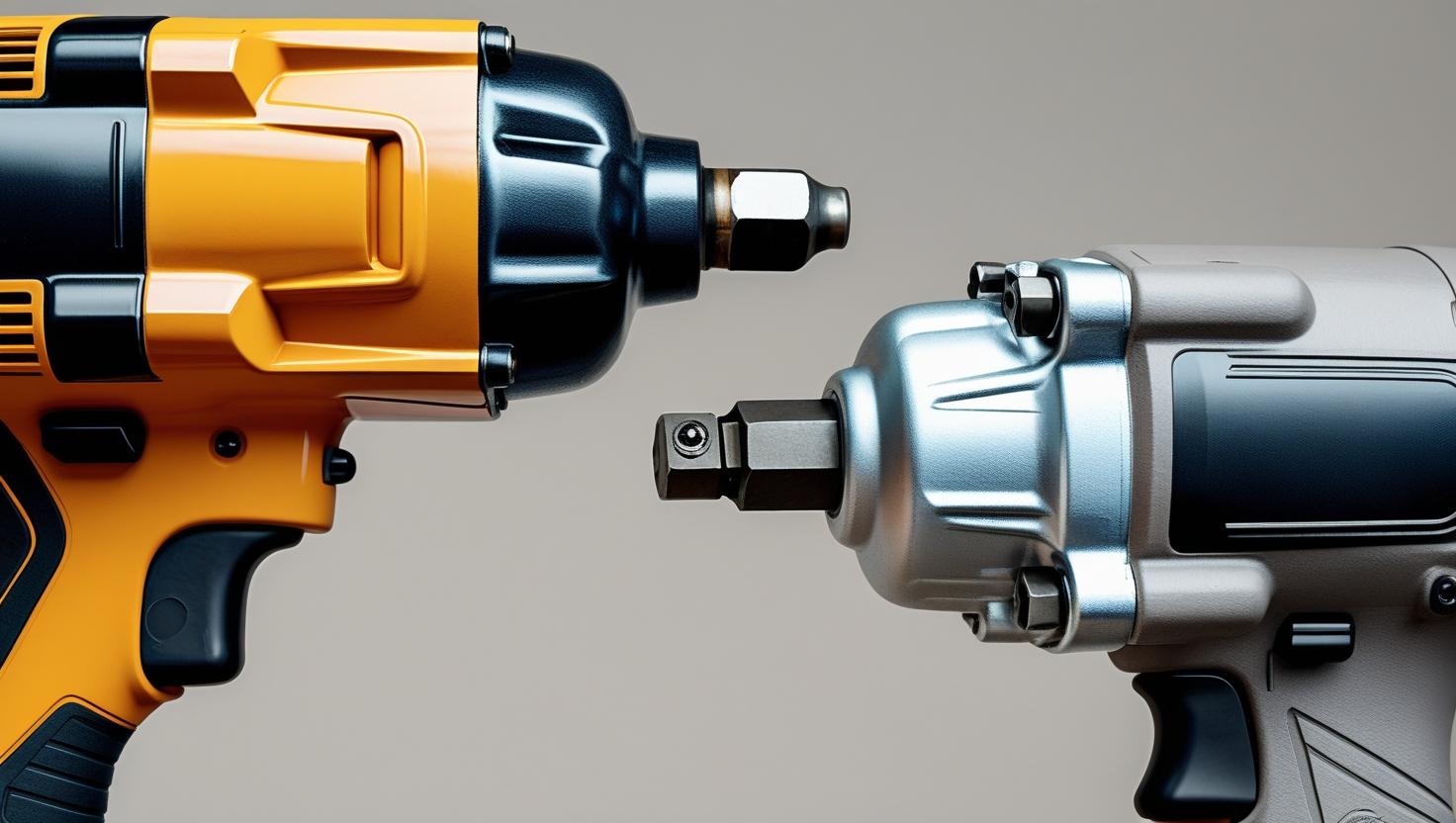

Electric vs Air Impact Wrench comparison is essential if you want the best tool for torque-heavy jobs, mobile repairs, or shop use. When it comes to choosing the right power tool for loosening stubborn bolts or tightening lug nuts, the battle often boils down to electric impact wrench vs air impact wrench. Each tool has its own strengths and weaknesses, and selecting the right one can drastically affect your workflow and productivity. In this comprehensive guide, we break down the pros and cons of both types of impact wrenches, examine use cases, performance, cost, and more—so you can make an informed decision.

What Is an Impact Wrench and How Does It Work?

An impact wrench is a high-torque power tool designed to deliver strong, sudden bursts of rotational force. It is a must-have for mechanics, construction crews, and anyone handling stubborn bolts, lug nuts, or heavy fasteners. Whether it’s a cordless impact wrench, electric impact wrench, or air impact wrench, these tools are indispensable in automotive repair, equipment maintenance, and industrial applications.

All impact wrenches rely on a hammering mechanism that stores energy in a rotating mass and suddenly releases it to the output shaft. This rapid, high-torque delivery makes impact wrenches far more effective than standard drills or manual torque wrenches when removing rusted or over-torqued fasteners.

Thanks to their speed and efficiency, impact wrenches provide the muscle needed for tasks that would be time-consuming or even impossible with conventional tools.

What Are the Two Main Types of Impact Wrenches?

There are two types of impact wrenches most commonly used: the electric wrench (including cordless) and the air wrench (also known as pneumatic). Understanding the differences between electric and air impact wrenches is key before investing in one.

- Electric Impact Wrench: Runs on electricity, often cordless and powered by a battery. These tools are suitable for remote work and offer plug-and-play convenience without the need for compressed air.

- Air Impact Wrench: Powered by compressed air from an air compressor, requiring an air hose and consistent air pressure. These models are preferred in professional settings for their high torque and durability.

How Does a Cordless Electric Impact Wrench Compare to a Pneumatic Tool?

Cordless electric impact wrenches have seen significant improvements thanks to modern battery technology, making them a top choice for many users. These tools offer excellent portability, quieter operation, and easy setup—making them ideal for mobile technicians, on-site mechanics, and anyone working outside traditional workshop settings. With no need for an air hose, air compressor, or fixed air supply, setup is simple and fast, even in remote areas.

On the other hand, pneumatic impact wrenches—also known as air-powered impact wrenches—deliver superior torque output and are preferred in professional environments where a powerful air compressor and stable air supplyare readily available. These tools are typically lighter because they don’t carry a battery or electric motor, reducing strain during extended continuous use.

In summary, cordless electric impact wrenches offer freedom and flexibility, especially for users on the move. Meanwhile, air impact wrenches are ideal for high-volume, high-demand applications in fixed locations, where consistent, reliable performance is critical.

Which One Provides More Torque?

In most cases, air impact wrenches provide higher torque than their electric counterparts. This makes air impactsbetter suited for heavy-duty applications and continuous use in industrial settings where maximum force is required over extended periods. These tools are especially reliable when paired with a consistent air supply and properly calibrated air pressure.

However, advances in battery-powered impact wrenches have closed the gap significantly. Modern cordless impact wrenches feature improved battery technology, brushless motors, and enhanced torque control, allowing them to handle a wide range of demanding tasks. For mobile professionals, mechanics on the go, or DIY enthusiasts, premium cordless models now offer enough torque to rival mid-range pneumatic impact wrenches.

Ultimately, while air impact wrenches are ideal for environments where consistent power and continuous use are a priority, cordless impact wrenches provide a strong alternative with impressive performance and the added benefits of mobility and ease of use.

Is a Cordless Impact Wrench Right for You?

A cordless impact wrench is perfect for users seeking flexibility, mobility, and convenience in their day-to-day work. Unlike traditional tools tethered to a power cord or dependent on a bulky air hose, cordless models offer the freedom to work efficiently across varied job sites without the hassle of setup or external equipment.

These tools excel in environments where speed, portability, and adaptability are key—such as roadside repairs, remote construction zones, or quick maintenance jobs in tight or awkward spaces. Because they are powered by rechargeable batteries, they eliminate the need for an air compressor or outlet access.

Modern cordless models are engineered with brushless motors, advanced electronics, and improved battery life that often provide enough power to handle 90% of common fastening and loosening tasks. Whether you’re a DIY enthusiast or a professional technician, a cordless electric impact wrench can be a highly versatile and dependable tool in your arsenal.

What Features Should You Look for in an Impact Wrench?

Before making a purchase, it’s essential to evaluate the key features that define an effective and efficient impact wrench—whether you’re buying a cordless or air-powered model.

- Torque Rating: Measured in ft-lbs or Nm, torque indicates the tool’s turning power. Higher ratings are ideal for demanding tasks like automotive repair or construction.

- Battery Voltage & Capacity (for cordless): Cordless models typically range from 18V to 24V, and higher Ah ratings mean longer runtimes.

- Drive Size: The most common sizes are 1/2″, 3/8″, and 3/4″. Choose based on the type of sockets and fasteners you regularly use.

- Speed & Torque Settings: Multiple settings allow for greater control over fastening and loosening tasks, preventing over-tightening.

- Weight and Ergonomics: Lightweight models with comfortable grips reduce fatigue, especially during extended use.

- Additional Features: LED lighting, brushless motors, and integrated battery indicators can improve usability and performance.

Whether you’re a professional technician or a DIY enthusiast, focusing on these factors will help you select an impact wrench that aligns with your specific workload and comfort preferences.

What Are the Pros and Cons of Electric vs Air Impact Wrenches?

| Feature | Electric Impact Wrench (Cordless) | Air Impact Wrench |

|---|---|---|

| Pros | – Portable and easy to maneuver – No need for air compressor – Works anywhere with battery or outlet | – High torque output – Lightweight for size – Durable for continuous use |

| Cons | – Lower torque than air models – Requires charging and battery management – Heavier due to battery and motor | – Requires air compressor and setup – Limited mobility – Loud operation |

How Important Is Battery Life in Cordless Tools?

Battery life is a major factor when choosing a cordless electric impact wrench. Look for models with high-capacity lithium-ion batteries, fast charging, and swappable packs to reduce downtime.

Compared to air tools, which rely on air pressure, the battery runtime can dictate your efficiency, especially on job sites without charging access.

Should You Use an Air Tool or Go Cordless?

The choice between cordless and air depends on your working conditions. If you already use air in your shop and require torque for tasks like changing tires or engine repair, a pneumatic impact wrench is the logical choice. These tools are built for continuous use, provide consistent performance, and are ideal when an air supply is already integrated into your workspace.

However, if mobility, convenience, and ease of use are priorities, cordless tools offer freedom that air wrenches can’t match. A cordless impact wrench eliminates the need for an air hose, air compressor, and outlet access, allowing you to work in tight spaces, remote job sites, or unpredictable environments. This makes them perfect for quick fixes, fieldwork, and on-the-go tasks.

When deciding between the two, consider not only the torque and task at hand but also your access to infrastructure like an air compressor or charging setup. Whether you need power for industrial applications or flexibility for everyday jobs, the choice between cordless and air should align with how and where you use your tools.

Are Electric Impact Wrenches More Expensive?

Cordless electric impact wrenches tend to have a higher upfront cost compared to pneumatic impact wrenches. This is primarily due to the inclusion of high-performance batteries, chargers, and advanced electronics. When purchasing a cordless model, you may also need to invest in additional battery packs to ensure continuous operation on demanding jobs.

However, the total cost of ownership over time can be lower. Since electric models don’t require an air compressor, air hose, or ongoing compressed air system maintenance, users can save on both equipment and energy costs in the long run. Plus, they offer unmatched convenience by working off-grid or in remote locations where air supplyinfrastructure isn’t feasible.

On the other hand, while air impact wrenches are usually cheaper to buy individually, they require a fully functioning pneumatic setup, including a durable air compressor, air lines, and routine servicing. This means the true cost adds up quickly, especially for those without an existing setup.

Ultimately, your total investment should be evaluated based on frequency of use, work environment, and whether or not you already own air tools or a compressed air system.

How Do You Choose the Right Impact Wrench?

Choosing the right impact wrench requires evaluating your work habits, environment, and long-term needs. Consider the following questions:

- What is your primary use case? Are you working in a fixed garage, on remote job sites, or performing mobile roadside assistance? Stationary setups often benefit from air tools, while mobile applications are ideal for cordless models.

- How much torque do you need? Heavy-duty applications like lug nut removal or suspension work may demand the higher torque of an air impact wrench. For everyday tasks, many battery impact wrenches provide more than enough power.

- Do you already have an air system in place? If you own a reliable air compressor, hoses, and accessories, a pneumatic tool may be more cost-effective.

- Do you value portability and simplicity? If freedom from cords and hoses matters more than brute force, a cordless electric impact wrench will be a smarter choice.

By weighing these considerations, you can confidently match the right impact tool to your projects and workspace without over- or under-spending.

Final Thoughts: Cordless Impact Wrench vs Air

When comparing cordless and air impact wrenches, it’s clear that each type serves a distinct user profile and work environment. Choosing between a cordless impact wrench and an air impact wrench ultimately comes down to weighing portability, power, and infrastructure needs. Each tool excels in different environments and use cases.

If you work in a fixed location with access to a reliable air compressor, and your tasks demand maximum torque and continuous use, a pneumatic impact wrench offers exceptional performance and long-term durability. However, if you’re frequently on the move, value flexibility, or work in areas without a stable air supply, a cordless impact wrenchprovides unmatched convenience and ease of use.

There is no universally superior option—only what best fits your working style, task requirements, and available resources. Assessing your day-to-day needs carefully will help you make the most cost-effective and functional choice.

Summary: What to Remember When Choosing Electric vs Air Impact Wrench

- Impact wrenches provide high torque, ideal for automotive and heavy-duty work.

- Two types of impact wrenches dominate the market: electric (cordless) and air (pneumatic).

- Air impact wrenches provide higher torque, best for industrial use.

- Cordless tools offer unmatched flexibility and ease of use.

- Battery life and battery impact power are crucial for electric models.

- Pneumatic tools need an air compressor, air line, and constant air pressure.

- Consider pros and cons, initial investment, and intended use.

- Cordless impact wrench vs air ultimately comes down to portability vs raw power.

No matter which you choose, impact wrenches offer efficiency and strength that traditional tools simply can’t match.